CHICAGO PNEUMATIC COMPRESSORS

CPM Series (3HP – 7.5 HP) - Industrial Rotary Screw Silent Air Compressors

CPM Screw Compressor ranges from a 3-7.5 HP compact air compressor which is ideal for tire shops, paint shops, automotive dealerships and related verticals. The tank-mounted compressor with dryer is tailored to installations that need to produce compressed air with a low dew point. With excellent performance results the compressor assure reliability and longer life as compared to that of a piston compressor and thus give quality compressed air. When compared to piston compressors, the exceptional efficiency of the CPM and the high output of the package ensure reduced power consumption, maximized output (capacity) and low cost per CFM produced.

CPA Series (7.5 HP – 20 HP) - Industrial Rotary Screw Silent Air Compressors

A flexible drive rotary screw air compressor is known for decade with a strong reputation of quality and top performance. This series is available in power ranging from 7-20 HP.

Floor-mounted Series

Especially suitable for installations near which compressed air is needed or as an extension to existing installations.

Tank-mounted Series

Especially suitable for installations that need to produce compressed air with a low dew-point. The unit consists of a compressor, a tank and a refrigerating dryer using R 134 gas: it features a dew-point indicator and timed condensate discharge. When oil-free compressed air is required, the unit can be fitted with a series of de-oiling filters.

Note : Unit performance measured according to ISO 1217 Ed 3 Annex C. 1996. Noise level measured according to Pneurop / CAGI PN8NTC2

CPB Series (20 HP – 40 HP) - Industrial Rotary Screw Silent Air Compressors

A flexible drive rotary screw air compressor with high-efficiency compression system to maximize productivity. It is a unique design available in three product variants range. The capacity of CPB series ranging from 15-30 HP guarantees constant performance over time.

Maximize productivity with reliable compressed air solution.

• Reduced energy consumption for optimum output.

• High product efficiency.

• Cost savings on maintenance and energy consumption.

• ES4000 24*7 Compressor Surveillance User Friendly.

• High quality components ensures maximum longevity in operating conditions.

• Easy access to every service points.

• Specially designed for India's tropical conditions.

The new Flexible Drive Rotary Screw Air Compressor lowers the power costs and consumes only 57% electricity which is a less power consumption as compared to the old design which was 88%.This saves 30% ( for IVR) of the electricity and makes the new design more environment friendly.

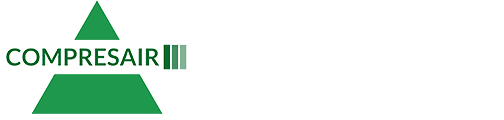

CPC (40 HP – 60 HP) INDUSTRIAL ROTARY SCREW SILENT AIR COMPRESSORS

The gear driven rotary screw air compressors with new product dimension comes with gear drive technology for energy efficient production. The gear driven transmission maximizes machine output for the given pressure and power. The series range from 40 HP- 480 HP. Maximize productivity with reliable compressed air solutions. The gear driven range of oil-injected screw compressors is the true standard in the industry. The components have been carefully selected to assure optimal quality and reliability. While the footprint is reduced due to the smart transmission system and component arrangement, performance is guaranteed thanks to the in-house designed air end.

CPD (75 HP – 100 HP) INDUSTRIAL ROTARY SCREW SILENT AIR COMPRESSORS

The gear driven rotary screw air compressors with new product dimension comes with gear drive technology for energy efficient production. The gear driven transmission maximizes machine output for the given pressure and power. The series range from 40 HP- 480 HP. Maximize productivity with reliable compressed air solutions. The gear driven range of oil-injected screw compressors is the true standard in the industry. The components have been carefully selected to assure optimal quality and reliability. While the footprint is reduced due to the smart transmission system and component arrangement, performance is guaranteed thanks to the in-house designed air end.

CPE (100 HP – 150 HP) INDUSTRIAL ROTARY SCREW SILENT AIR COMPRESSORS

The gear driven rotary screw air compressors with new product dimension comes with gear drive technology for energy efficient production. The gear driven transmission maximizes machine output for the given pressure and power. The series range from 40 HP- 480 HP. Maximize productivity with reliable compressed air solutions. The gear driven range of oil-injected screw compressors is the true standard in the industry. The components have been carefully selected to assure optimal quality and reliability. While the footprint is reduced due to the smart transmission system and component arrangement, performance is guaranteed thanks to the in-house designed air end.

CPF (180 HP – 340 HP) INDUSTRIAL ROTARY SCREW SILENT AIR COMPRESSORS

The gear driven rotary screw air compressors with new product dimension comes with gear drive technology for energy efficient production. The gear driven transmission maximizes machine output for the given pressure and power. The series range from 40 HP- 480 HP. Maximize productivity with reliable compressed air solutions. The gear driven range of oil-injected screw compressors is the true standard in the industry. The components have been carefully selected to assure optimal quality and reliability. While the footprint is reduced due to the smart transmission system and component arrangement, performance is guaranteed thanks to the in-house designed air end.

Inverter Driven Variable Speed Drive Compressors

The IVR Screw Air Compressor series saves over 35% power and consumes less energy, thus ensure you big savings and is environmental friendly

• IVR machine varies capacity to suit your air demand for saving power.

• Built-in IVR drive for maximum reliability.

• Factory-tested machine at critical speed to minimize vibration/resonance risk.

• Eliminates unloading power to almost 0%

• Ensures fastest payback.

• Promises lowest operating cost.

• Regulates pressure within 0.1 bar.

• Assures constant power factor.

• Guarantees easy maintenance.

• Assures reduced carbon

dioxide emissions saving environment

PERMANENT MAGNET MOTOR VARIABLE SPEED DRIVEN SCREW COMPRESSORS

With the new leap in Energy Efficiency- iPM technology in screw compressors Chicago Pneumatics' new leap in Energy Efficiency with Innovative iPM technology in screw compressors. Launching our all new series of CPMV & CPVS PM screw compressors which is maintenance-free and energy saving ensuring lower total cost of ownership

Why choose CP iPM motor compressors?

The All new iPM motor series compressor was designed to deliver a complete One stop solution for all your efficient compressed air needs :

• In-house designed iPM motor

• IE4 Super Premium Efficiency (96% – 97%)

• Direct drive configuration for enhanced savings

• Latest IP Protection class

• Proven Oil cooled design

• Horizontal configuration for easy maintenance

• 100% ’In-House’ design

IE4 Super Premium Efficiency iPM motor offers upto 5% energy savings vs. IE2 / IE3 induction motor

Spiral AIR - 100% Oil Free Air Compressors

100% oil-free scroll compressor provide high-quality compressed air for critical applications in wide range of industries such as pharmaceuticals, food and beverage, electronics and textiles that cannot risk any chance of oil contamination in their processes. Range from 2-30 HP

Spiral AIR known for ultimate 100% oil-free clean air contains no filtration system to remove oil along the network. Equipped with high-efficiency IE3 motor these machines an energy efficient that does not unload power consumption. These machines are made of high quality material that require minimal number of moving parts, minimal service interventions and no oil change and oil waste management thus ensuring long operating life.

Features:

• ISO 8573-1 Class 0* certified quality air.

• Corrosion proof material.

• Ambient temperature sensor

• Identification & logging of shutdowns.

• Adjustment of service schedule.

WisAIR - 100% Oil Free Air Compressors

100% oil-free water injected screw compressor provide high-quality compressed air for critical applications in wide range of industries such as pharmaceuticals, food and beverage, electronics and textiles that cannot risk any chance of oil contamination in their processes. Range from 20-75 HP

WisAIR known for ultimate 100% oil-free clean air is integrated with air dryer that enhances the air quality and protects your air network against corrosion. The low air discharge temperatures, optimized rotor profiles and no bearing losses makes the machine most energy efficient compressor. Its integrated inverter technology assures a perfect match of air supply and air demand eliminating no load power losses. WisAIR is made of durable material to exclude any risk of corrosion thus making it a reliable product.

• ISO 8573-1 Class 0* certified quality air

● Integrated dryer guarantees PDP < 3°C.

● Corrosion proof material: aluminium bronze rotor housing, stainless steel rotor shaft, piping and separator vessel.

● Smooth start up with inverter driven technology.

● Clean piping.

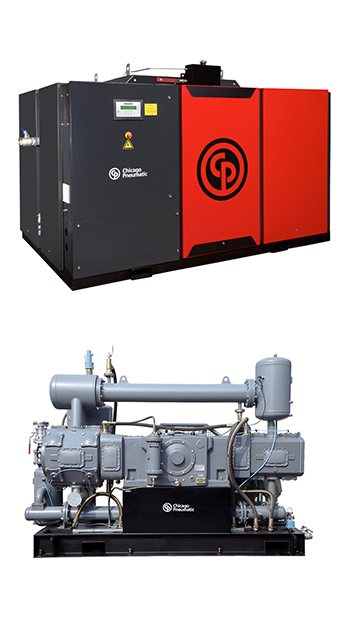

High Pressure PET Air Compressor

100% oil free quality air supplying compressors especially for PET blowing industry. The wide range of standard or customized model are designed for 24 hours operation, years after years...

High Pressure PET Air Compressor - Both canopy and open type for your PET blow moulding operations. Power efficient, low reciprocating masses with lower inertia loads and lesser friction. Compact, small foot print and easy to install design ranging from 25-335 HP.

Features:

• Energy savings & flexibility with ES 4000 controller. - Integrated factory fitted VFD.

• Standardization of parts, easy & faster availability. - Easy maintenance and easy access to every subpart.

• Proven piston technology, robust 3 stage compression design.

• Factory fitted air/water interconnection with control panel. - All components on common base plate.

• Oil free cylinders with PTFE piston rings and bearings for extended life. - Extra-long distance piece, ensure separation of oil from compression chamber.

Oil Free Reciprocating Compressors

Chicago Pneumatic Sales offers 100% oil free quality air supplying compressors especially for power plants, pharmaceuticals and food and beverage applications. The wide range of standard or customized model are designed for 24 hours operation, years after years...

Features:

• 100% Oil Free Air Compressors

• Energy savings with VSD

• Compact self-contained package

• Environment friendly

• Reliable electronic control

• In-built IVR drive models

Refrigerant Air Dryers

It is impossible to imagine present-day production and process sequences without compressed air. As modern day industries are increasingly imposing ever high quality demands, it is not just a matter of producing certain quantity of compressed air but also of confirming with defined purity criteria. Thus, the need for pure and dry compressed air is of paramount importance.

The CPZ refrigerant dryers guarantee dry and qualitative compressed air which prologues the lifetime of your equipment and ensures a superior production quality. Water vapor is eliminated, avoiding corrosion in your compressed air network and tools. All in all this lowers your maintenance costs and improves your overall production process for complete peace of mind.

Heatless Air Dryers - (250 CFM ~ 460 CFM capacity)

• Compressed Air Quality : ISO 8573.1 2010 Class 1-2-1 Compliant

• Reliable operation with high quality Change over valve

• Consistent dew point of -40°c with high quality & efficient desiccant for the right application.

• Reduce purge loss up to 4% ~ 10% with Purge control option based on dew point

• Minimal risk of crushed desiccant thanks to the optimized nozzle and the large vessel diameter.

• Counter-current regeneration for optimal energy efficiency and guaranteed dry air

• High reliability and robust design

• Low noise levels while purging with efficient silencer

Air Line Filters

Atmospheric air already contains impurities like: dust, various forms of hydrocarbons and water in form of humidity, which once sucked by the compressor, is compressed and delivered to the line together with eventual oily particles. These polluting agents when interacting with each other, generate abrasive and corrosive emulsions which can damage the distribution lines, the pneumatic devices and the product itself.

This leads inevitably to:

• Leakages of air in the piping

• Greater maintenance costs for the machine using it

• Production losses

• Loss in product quality

The growing automation of plants, the use of more and sophisticated devices requires compressed air, which is of a better quality. Line Filters of Chicago Pneumatic can hold and remove those polluting agents that can, damage the regular operation of the production cycle.